The purification of aluminum alloy melt is the prerequisite for obtaining high-quality castings. Due to the inhalation and oxidation of raw materials and during the……

With the development of science and technology, automotive, shipbuilding, aviation, aerospace, and other manufacturing industries have increasingly higher quality requirements for aluminum alloy castings. In……

During the casting production, the aluminum alloy melt is solidified in the mold. During the solidification of the aluminum alloy melt, the hydrogen atoms in……

In the modern equipment manufacturing industry, “lightweight” has become the consensus of material selection. Especially in the fields of modern aerospace, transportation, light industry and……

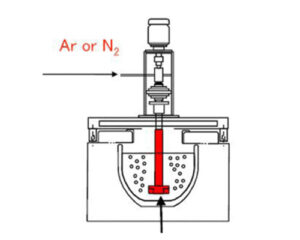

The degassing principle is different for different degassing unit. At present, the two inert gases commonly used in the degassing process are nitrogen and argon.……

As we all know, because aluminum alloy wires have incomparable performance with ordinary steel core aluminum stranded wires, aluminum alloy wires have been widely used……

In recent years, with the promotion of energy saving and environmental protection concepts, various vehicles have developed in the direction of lightweight. At present, most……

AdTech provides degassing filtration systems, refining agents, nozzle plates, launders, front boxes, flow control accessories for aluminum strip casting. AdTech produces high-quality refractory materials, and……

Purification of aluminium is mainly degassing and slag removal, so a series of advanced purification technologies are used in the smelting furnace, such as using……

The main goal of aluminum melt purification technology is to continuously improve the purity of the melt, pursue efficient and economical purification technology for aluminum,……