Aluminium Liquid Filtration is the most effective and reliable method to remove non-metallic inclusions in aluminum melt. There are many kinds of filtration. The simplest……

The quality of aluminum melt determines the quality of final products to a great extent. In particular, there are hydrogen content, more inclusions, and less……

The heater must be preheated according to the heating curve time when the CFF System is used for the first time, shut down for a……

Aluminum Degassing Methods Aluminum Degassing Methods used in the aluminum foundry mainly include the Air Liquide method, Snif method, Alpur method, in-line degassing system, and……

At present, the on-line degassing methods commonly used in aluminum alloy casting process are: SNIF method, ALPUR method, RDU method, MINT method, etc. no matter……

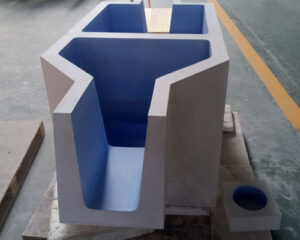

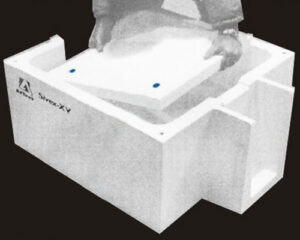

Ceramic Foam Filter Filtration principle is the same as that of ceramic tube filtration. It is a deep filtration mechanism, which has a higher porosity……

Smelting and cast rolling production belongs to the scope of metal material processing, mainly physical processes. The basic theory is metal physics. For aluminum, its……

Aluminum Casting Fluxes are mainly a mixture of chloride salt and fluoride salt and other additives. Most fluxes are based on KCl and NaCl. Another……

Although most of the slag inclusions are removed from the aluminum melt during refining, some fine slag particles, especially slag particles below a few microns,……

The non-metallic inclusions in the aluminum melt will show surface cracks and pinholes during the aluminum foil rolling process. Surface intimacy is also a defect……