Aluminium Alloy Melting is a process in which a solid heats up and becomes a fluid liquid. After the feeding is completed, melting starts. During……

The basic purpose of aluminum alloy smelting is to obtain an aluminum alloy melt with a chemical composition that meets the production requirements and high……

Granular fluxes are usually composed of chlorides and fluorides as well as additional additives to give special properties. Flux is used to describe all aluminum……

In order to protect its position in the global automotive industry, aluminum foundries must meet or exceed higher technical specifications to provide better quality and……

Degassing aluminum with nitrogen is an economical degassing method. In aluminum foundry, it is a common practice to degass molten aluminum with argon gas. It……

Degassing Molten Aluminum is one of the most effective purification methods for aluminum. With the increasing demand for non-ferrous metal castings (especially aluminum and aluminum……

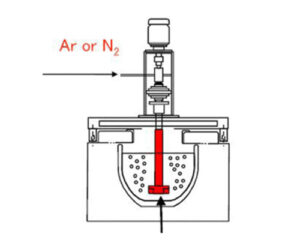

Rotary degassing is one of the most effective degassing methods by using inert gas (nitrogen). Reducing hydrogen content in molten aluminum before casting is one……

The rotating degassing box impeller works by increasing the surface area of the inert gas introduced into the metal. The smaller nitrogen bubbles produced by……

Ceramic Foam Filter Installation is closely related to the ceramic foam filter filtration efficiency. At the same time, it is not necessary to reduce the……

Online aluminum degassing system is commonly used in the market. The online aluminum degassing unit has high degassing and refining effect, and the heating system……