In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Foam Ceramic Filters were originally developed for forging aluminum alloy. These Forging Aluminum Alloy required strict cleanliness to meet the strict product application, such as……

Metal purity is one of the most important requirements in the foundry industry. The best practice in the field of molten metal filtration is to……

Foam Furnace Filters are used to filter molten aluminum in the foundry. Our ceramic foam filters have a 3D mesh structure, high porosity, and low……

Porous Ceramic Filters are phosphate-free high alumina-based products with high porosity and mechanochemical stability. They have excellent resistance to molten aluminum thermal erosion and corrosion.……

Alumina ceramic foam filters can effectively remove solid state mixed with molten metal, so aluminum alloy can be successfully forged, aluminum foil is manufactured, and……

Hydrogen degassing from melt can improve the quality of aluminum. In Adtech, metal processing includes flux injection and rotary degassing. Hydrogen is an impurity, and……

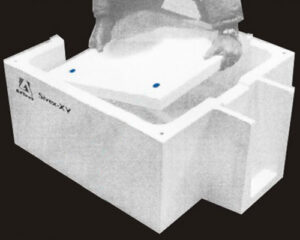

Rotary Degassing Equipment is an automatic metal processing system for environmental degassing and cleaning of aluminum and copper alloys. The rotating degassing equipment adopts the……

How To Degas Aluminum? The degassing treatment of the melt causes the injector immersed in the melt to rotate so that the scavenging gas (usually……

Methods Of Degassing In Foundry are used by most aluminum foundry. Casting is a common metal and alloy forming technique in which liquid or molten……