The aluminum liquid removed from the aluminum electrolytic cell contains many impurities, which not only affects the casting and processing performance of metal aluminum, but……

When scrap aluminum refining, especially when the aluminum concentration is less than 50 wt%, particles of glass, oxides and stones are usually very harmful. When……

If the structure and design principle of the die-casting mold are not good, it will not only bring difficulties to the die-casting mold manufacturing, but……

The metallic element aluminum is the third most plentiful element in the earth’s crust, comprising 8% of the planet’s soil and rocks (oxygen and silicon……

Aluminum products are widely used. To obtain pure aluminum products, aluminum foundry must go through the extraction and refining aluminum process. Known deposits of bauxite……

Aluminum and its alloys oxidize readily in both the solid and molten states to provide a continuous self-limiting film. The rate of oxidation increases with……

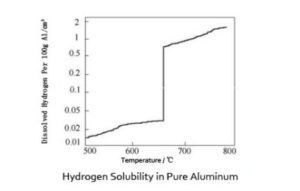

Hydrogen Influence on Aluminum is obvious. Hydrogen is the only gas that is appreciably soluble in aluminum and its alloys. Its solubility varies directly with……

In the production process of die-casting, in order to improve the service life of the mold cavity and punch, and make the die-casting parts demold……

Aluminum is guided into the casting machine from the melting furnace through the launder and storage tank. Launders with steel sleeves are lined with refractory……

The advanced ceramic boron nitride coating is an easy-to-use and widely used product. It has excellent lubricating properties, non-wetting properties, and good high-temperature stability. Even……