Ceramic foam filter is a new type of ceramic filter material developed in recent years, it is widely used in molten metal filtration. It is……

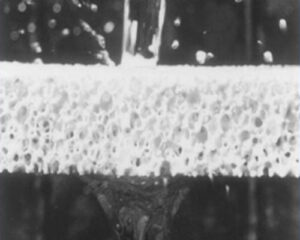

Foam ceramic filter plates are commonly used for aluminum liquid filtration. When the molten aluminum passes through the pores in the ceramic foam filter, the……

Refining purification is a process of removing gases, inclusions and harmful elements from the melt, and obtaining good aluminum liquid. There are many refining purification……

When the secondary aluminum alloy melt is cooled, the solid non-metallic impurity is distributed on the grain boundary, which will reduce the mechanical properties of……

Aluminum scrap recycling such as beverage cans, as long as the color on the outer surface is removed, is sent into the furnace and melted……

The solid non-metallic particles suspended in the molten metal can cause serious difficulties in the aluminum casting and manufacturing process. Ceramic Foam Filters are particularly……

The filter box is the last process for aluminum melt treatment, which is very important for product internal quality control. In the production process of……

The aluminum melt is filtered by the online metal degassing device and the filtering device, and then flows into the front box for casting and……

AdTech provides a foam ceramic filter for aluminum casting, which has high thermal shock resistance, high corrosion resistance, sufficient strength, economical production, is more environmentally……

The open-cell foam ceramic filter used in aluminum foundries was developed in the early 1970s, and the technology was first commercially applied in 1974 to……