Rusal aluminum casting filter mainly adopts ceramic foam material as filter medium. The ceramic foam filter has a unique three-dimensional connected curved pore network skeleton……

Ceramic foam filter is used as the Dubai aluminum foundry filter, it can effectively filter the primary and secondary liquid solid non-metallic inclusions in the molten……

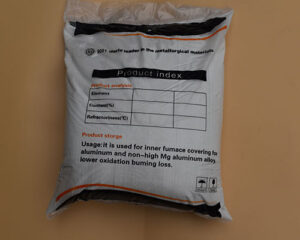

The cast house flux is mainly a mixture of chloride and fluoride salts and other additives. Most fluxes are based on KCl and NaCl, and……

The hydrogen content and non-metallic inclusions in aluminum and aluminum alloy melts have an important impact on the quality of secondary aluminum. Aluminum and aluminum……

The secondary aluminium smelting is to add a certain proportion of aluminum and aluminum alloy scraps into the smelting furnace, and after rapid melting, the……

Foundries flux is an indispensable auxiliary material in the smelting process of the secondary aluminum salt smelting process. In addition to being used as a……

Recycled aluminum alloy contains more metal and non-metal impurities and must be further refined. Refining methods include filtration, gas refining, flux refining, vacuum refining, and……

In the production of primary aluminum, approximately 273×10^6J of energy is required per ton of aluminum. The energy required to produce alumina accounts for about……

Refractory fiber is a fibrous heat-insulating refractory material. It has the characteristics of the general fiber, is soft, elastic, and has a certain tensile strength.……

Headbox (front box) installation is important for aluminum liquid level control accuracy, it is one of the key factors affecting the quality of ultra-thin fast……