The degassing and filtration composite purification method is a mature composite purification technology with the dual functions of degassing and impurity removal. It has been……

The aluminum fluxes refining method has a good effect on discharging non-metallic inclusions. The degree of purification by the flux to remove non-metallic inclusions in……

Metal refining treatment can remove or minimize the gas and oxide inclusions in the regenerated aluminum alloy melt, so as to improve the degree of……

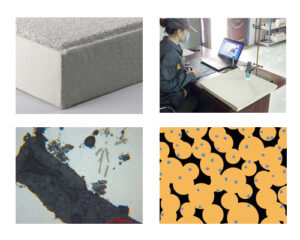

The molten aluminum refining fluxes are mainly used for degassing and removing inclusions of metal melt. AdTech refining flux is white powdery fine particles. The……

There are many types of fluxes used for aluminum alloy smelting, which can be divided into two categories: covering agent and refining agent. The molten……

The aluminum smelting furnace can be divided into two basic types-round smelting furnace and rectangular smelting furnace. Both types of aluminum smelting furnaces can be……

At the deep bed filter device outlet, the melt’s quality is better after a series of online treatments such as degassing and filtering. The slag……

Molten metal, especially molten aluminum, often contains solid substances, which can affect the quality of the casting. After the molten metal has solidified, this solid……

In order to remove the slag and gas in the melt, in addition to the use of flux refining and degassing filtration equipment for purification,……

The online refining methods outside the furnace include the MINT method, SNIF method, ALPUR method, FILD method, and so on. Most of these online refining……