1 Ceramic Foam Results Discussion 1.1 Priming and wetting ceramic foam is normally operated in a ” filter Bowland is primed using a gravity head……

Aluminum ceramic foundry filters are affected by magnetic fields 1 Introduction Premium quality aluminum castings require a high level of metal cleanliness and are crucial……

Characteristics of Porous Ceramics 1. Thermal shock stability Foam ceramics are often used on occasions where the temperature changes rapidly, and must have good thermal……

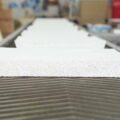

1 Characteristic of a new generation of ceramic foam filter molten metal filtration In order to achieve the research and development goals we determined, a……

reliable ceramic foam filter manufacturers The smelting of aluminum alloy is an important part of the aluminum alloy processing process, which is reflected in the……

Porosity Analysis of Ceramic Porous 1 Porosity The most basic parameter of ceramic porous should be an index that directly expresses the porosity analysis of……

Degassing aluminum technology improves 1. The turbulent flow phenomenon on the surface of molten aluminum cannot be effectively solved With the increase of more and……

aluminium degassing components determine the quality of the degassing. Let’s talk about the components of the degassing device. 1. Immersion heating device To make up for the……

Porous ceramic production, this article introduces several of the production methods. 1. Ion exchange method Layered sodium silicate crystals and hexadecyltrimethylammonium bromide are thoroughly mixed……

Regarding”ceramic foam filters for casting“, there are the following common methods: 1. Freeze-drying The full name of the drying method is vacuum freeze drying, which……