The aluminum online degassing system is important equipment for the production of aluminum alloy. It can reduce the hydrogen melted in the solid metal and……

AdTech degassing device is an environmentally friendly automatic molten metal treatment system, which performs degassing and slag removal of aluminum alloys. The box structure of……

The rotating rotor degassing method can give full play to the hydrogen removal advantages of the bubble floatation method. The key is that the liquid……

The method of molten metal refining is to use fluxes for effective refining. The metal refining process converts certain impurities or oxides into compounds and……

Aluminum alloy degassing flux not only has strong slag removal and slag removal capabilities, but also has excellent degassing capabilities, which can significantly increase the……

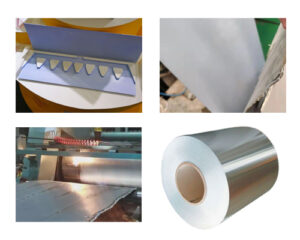

The casting nozzle is the “throat part” of the continuous casting and rolling mill that the aluminum melt is sent to, and its role is……

The aluminum casting tip and nozzle directly feed the aluminum melt into the double-strip continuous caster, it is the main component of the high-throughput aluminum……

The high-throughput continuous casting and rolling aluminum alloy production process use electrolytic aluminum liquid to directly equip the alloy solution. Then it passes through a……

Aluminum Foundry Fluxes have been widely used in aluminum and aluminum alloy casting production. Although flux products have continued to grow, the main components and……

In terms of secondary aluminum smelting technology, the commonly used degassing method is to spray gas into the aluminum alloy liquid, and use the principle……