Ceramic filter for aluminum melt filtration outside the furnace is an effective method to improve the cleanliness of molten aluminum. The ceramic filtration process can……

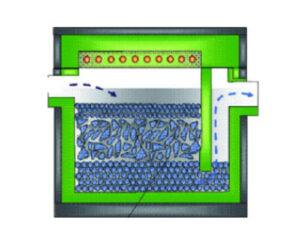

The online filtering device is used for on-line filtering of the aluminum melt outside the furnace, it can remove the non-metallic inclusions in the aluminum……

The material of the aluminum transfer launder can be divided into two categories: ceramic fiber and castable. The ceramic fiber launder has the advantages of……

The launder system for aluminum casting is divided into a direct flow trough, an inclined launder, a distribution launder, a corner launder, and a lifting……

High efficient flux purification is conducive to the improvement of production efficiency and the control of production costs, and has always been the focus of……

The fluxes for aluminum foundry remove the slag inclusion in the aluminum alloy melt mainly through three ways of adsorption, dissolution, and compounding. Adsorption mainly……

Generally speaking, aluminum purification in furnace includes flux method, gas refining method (active and degradable gas), vacuum purification, and field purification. Among them, flux purification……

CFF filtration efficiency is only related to the thickness of the filter and the speed at which the melt passes through the filter. The greater……

The Aluminum Melt Tubular Filter realizes the dual functions of surface filtration and internal adsorption and trapping of impurities. The basic working principle of the……

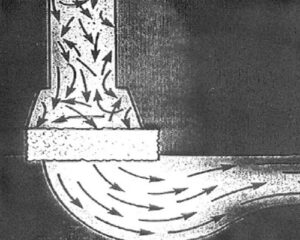

The deep bed filtration device consists of several layers of alumina balls and gravel layers. The particle size selection of the filter material and the……