The covering fluxes are used to cover the melt. These fluxes composed of salt compounds will form a liquid at the normal melting temperature of……

Alumina Ceramic Foam Filters for foundry are mainly for filtration of aluminium and aluminium alloys in cast house. They can effectively remove inclusions, have excellent……

The continuous caster nozzle is formed by compressing the felt of refractory fiber and coagulating the binder containing colloidal silica to form a rigid member.……

The continuous caster feed tip is made of refractory fiber felt, which contains approximately equal amounts of alumina and silica, and contains a solution containing……

In a vertical continuous casting machine, where the axis of the roller is in a horizontal plane, and molten metal is fed upward into the……

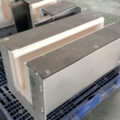

The molten metal feed tip for continuous caster is a pair of substantially rectangular refractory members, each having a downstream edge portion and an upstream……

The production of ingots and billets of aluminium and other non-ferrous metals usually includes a filtration step, in which the liquid metal is passed through……

The degassing and CFF filtering method is important for aluminum casting. It is a method of processing molten aluminum and aluminum alloys to remove solid……

In conventional casting systems, a metal launder typically has a plurality of metal discharge spouts, and spans a like number of casting stations. It is……

The cover of the launder construction comprises a metal cover, such as a steel jacket; at least one electrical resistor, which is arranged so as……