In China, the casting parameters of the casting process are basically in the manual or automatic control system. The foreign countries automatically control the casting process to achieve the reproducibility of the casting process and ingot quality, and the product quality is stable.

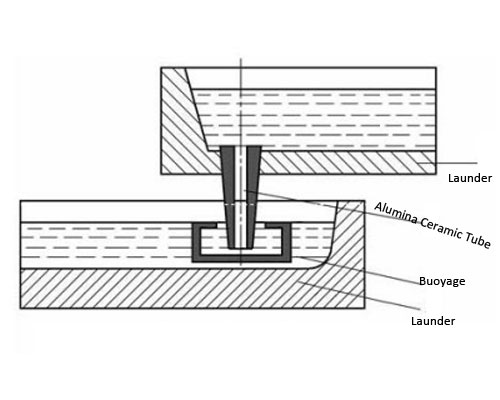

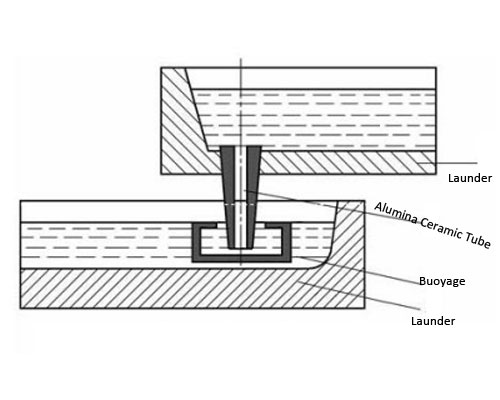

The liquid level in the domestic crystallizer adopts two methods: the buoy funnel at the lower port of the aluminum liquid guide tube of the distribution launder and the mechanical lever type of the buoy and the stopper to adjust the flow to control the liquid level. The level of the liquid level depends on the person, and the fluctuation is large. The liquid level in the foreign crystallizer adopts a laser measuring device and its automatic adjustment flow control system. The liquid level fluctuation is very small, up to ±1m, which can realize low metal level control.

The temperature of molten aluminum, casting cooling water flow, and casting speed of domestic casting depend on the different alloys and ingot specifications specified by the process. The casting process is realized by manual operation buttons. The temperature of water, molten aluminum and casting speed are separately controlled, and they can be indicated on the console or The displayed value is basically the same water flow and casting speed from the beginning to the end of the casting, and the mold has no lubrication system. The casting machine and its casting technology imported from abroad, the casting parameters of different alloys and specifications, as well as the beginning, normal, ending and transitional stages of casting, realize automatic casting control by computer.

The holding furnaces used in the automatic casting technology are all tilting, and the casting process is centrally controlled. The aluminum liquid level is controlled by a multi-link unit. The liquid level in the crystallizer and the liquid level in the launder are equipped with laser measuring devices. The laser sensor has a microprocessor. The combination of measurement and processing systems can obtain very high precision values. The flow rate of the holding furnace tilting is controlled by the casting machine PLC. The stopper rod that measures the liquid level in the mold and controls the flow of the liquid injected into the mold is installed on the beam. The laser sensor is kept at a certain distance from the aluminum liquid level, and different aluminum liquids are in contact. The beam is fixed on the distribution flow trough, and the same distribution flow trough is cast.

The casting automatic control system adopts PLC to control the entire casting process. The process parameter setting is menu-based, and the liquid level, lubricating oil quantity, casting speed, cooling water flow rate, molten aluminum temperature, stop time of pulse water, casting length, etc. in the computer menu will be carried out according to the procedure. After the alloy, ingot specifications and casting parameters are selected, the equipment must carry out a series of automatic inspections. After the inspection, the equipment is in the waiting state. At the beginning, the liquid level adjustment maintains the starting position, the liquid level in the mold is injected to the starting point of the curve, and the lifting platform of the casting machine starts to drop at the beginning speed, or spray pulsed water. After reaching the stop length and time of the pulse water, it will automatically switch to the normal casting stage, and the parameters will be carried out automatically. When the casting length reaches a certain distance from the preset point, an audible and visual alarm will be issued, and it will proceed with the end stage parameters. When the ingot length reaches the set point, the platform stops descending, the tilting holding furnace returns to the original position, the stopper rod closes the aluminum liquid port of the distribution flow trough, and one end of the distribution flow trough is lifted, and the remaining liquid aluminum flows out of the distribution flow trough. The distribution runner is removed together with the stopper, and the casting ends. Fully automatic process control system reduces the quality impact caused by human operation factors.

Buoy type flow controller, when the aluminum liquid level in the front box is too high, the buoy rises to reduce the gap, and the aluminum liquid entering the front tank from the flow tank decreases. At this time, the aluminum liquid level in the front tank will drop. The buoy-type controller is always in the process of dynamic balance. It is better to use refractory materials with lower density to make the buoy to improve its sensitivity.