The cast ceramic foam filter uses a special ceramic foam filter to remove the inclusions generated between the refining system and the mold table. The ability of cast ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the metal solidification process. Therefore, the quality and productivity of downstream operations such as forging, extrusion and rolling are guaranteed.

At Adtech, the constant pursuit is to ensure that our customers have access to the best technology available on the market to produce the highest quality billets, slabs or ingots for their customers. Our guarantee will not stop at our customers, but will continue to our customers’ customers! Our technology ensures the consistency of casting quality for the most critical final product applications.

Alumina ceramic foam filters are only used for aluminum castings. Currently, market-leading suppliers offer various sizes and thicknesses. You must choose the right one according to your requirements. If your requirement does not fit the general size, you can order a custom size. In order to avoid the re-oxidation of molten aluminum during the casting process, pressureless casting technology can be used. It increases the productivity of the manufacturer while preparing the filter for the next large shipment.

During the melting and casting of aluminum, bubbles, oxide films and non-metallic inclusions destroy the continuity of the metal structure, leading to stress concentration, reducing the performance of the casting, and reducing the processing performance. In order to avoid these hazards, the aluminum melt must be purified in two main ways:

Adsorption purification

Chlorine, nitrogen or other inert gases are introduced into the aluminum liquid filter. These gases and molten aluminum generate bubble chloride salts, which make impurities float or sink, thereby achieving the purpose of removing gases and impurities in molten aluminum.

Filtration and purification

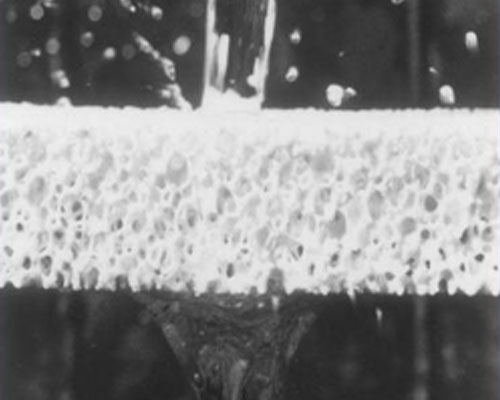

The molten aluminum flows into the alumina ceramic foam filter, and the inclusions are captured by the ceramic foam filter to purify the aluminum foam.

Liquid aluminum filter box is a special aluminum silicate filter box for the aluminum industry, usually we call foam ceramic filter box, steel shell filter box and aluminum silicate liner.

During the filtration process, the molten aluminum sweeps over the rent of the ceramic foam filter plate and flows along the zigzag channel and the gaps in the filter plate. The impurities in the aluminum melt are in contact with the surface of the filter plate channel under the action of deposition, inertia and interception. Impurities remain firmly on the filter plate under the influence of pressure, friction, surface adsorption, etc.