The caster tips and nozzle can continuously cast aluminum plates several meters wide and about one centimeter thick at a speed greater than one meter per minute for several days.

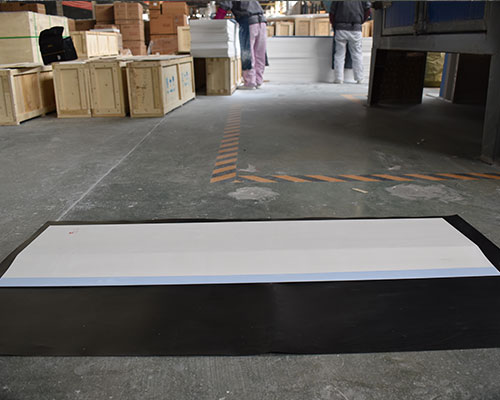

The molten metal casting tip nozzle for the continuous casting machine is a pair of substantially rectangular refractory members, each member has a downstream edge portion and an upstream edge portion, and each member is formed of a refractory fiber mat rigidly bonded together. The refractory fiber is compressed near the downstream edge portion to a greater density than the upstream portion of the member.

A device adjacent to the upstream portion is used to space a pair of members apart to form a metal feeding gap between the members, and to allow molten metal to enter the gap to flow toward the downstream edge portion. Among them, the thermal conductivity of the refractory fiber felt gradually increases from the upstream part to the downstream.

The front box and the Caster Tips and Nozzle directly affect the quality of the aluminum continuous casting and rolling, and the thickness of the aluminum rod can be controlled. The purification and flow control steps of the aluminum liquid in the early stage are well mastered, and the later work can be easy.

On-line degassing filtration is the key research and development object of major aluminum processing enterprises. The online refining treatment device adopts the rotating nozzle degassing method and the ceramic foam filtering method. The device adopts nitrogen (argon) gas or nitrogen and chlorine mixed gas refining and foam ceramic filtering technology, and is suitable for deployment on aluminum and aluminum alloy casting rolling and casting production lines to perform online degassing, removal of inclusions, removal of alkali metals, etc.

Our company mainly provides online degassing device, online filtering device and refractory materials for casting and rolling-front box, ceramic launder, caster tips and nozzle plate, etc.