Alumina ceramic foam filter is widely used in the casting molten aluminium filtration, can effectively remove various inclusions of aluminum melt, greatly improve the cleanliness of the metal, thereby improving product quality, reducing cost, and productivity has been improved to varying degrees. The operation is easy, the process is easy to control, and there is no need for excessive investment, which is worthy of promotion and application.

The casting molten aluminium filtration with foam ceramic filter is applicable to all aluminum production departments, including book plates, strips, foils, bars, pipes, wires, extruded materials, forgings, primary aluminum ingots, reclaimed ingots and continuous casting. Production of rolling stock, etc.

Advantages for Ceramic Foam Filter

- Adopt adsorption principle for filter, can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

- No broken bits drop out, effectively reduce the pollution of molten aluminum.

- Superior thermal shock resistance, improve erosion resistance ability of molten metal.

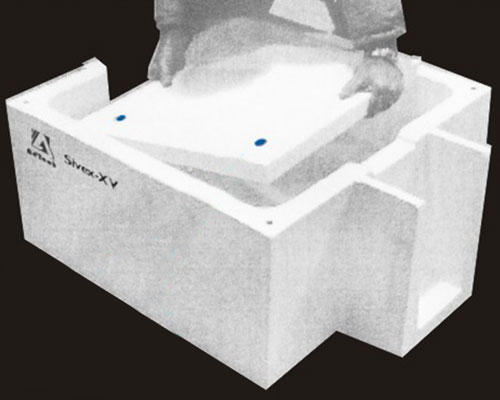

- Automatic flow production, 3 calibration procedure, precision size, fit the filter bowl tightly.

- Improve the surface appearance and performance, purify molten aluminum.

Standard sizes for Ceramic Foam Filter

Dimension (± 3 mm

): 7x7in 9x9in 12x12in 15x15in 17x17in 20x20in 23x23in 26x26in

Thickness: 50 ± 2 mm

Bevel Angle: 17.5± 1.5°

Special Dimension: square

The casting molten aluminium filtration efficiency of the AdTech ceramic foam filter depends on the pore size of the filter plate, the size and type of inclusions (density, wetting characteristics) and the speed at which the molten metal passes through the filter plate.

It is surrounded and sealed by expanded gasket with 200% expanding above 450°C to prevent floating and leakage of aluminum liquid through the contact surface.

Filtered by the adsorption principle, it can effectively remove large inclusions in the aluminum liquid, and effectively adsorb fine inclusions of micron size, and the filtration efficiency of the same ppi is high.

A sealing gasket is applied around the ceramic filter plate to act on the contact surface of the filter plate and the filter box to prevent leakage of the aluminum liquid through the contact surface. Our filter plates are made of three different types of sealing gaskets including fiber paper sealing; fiber cotton sealing; expandable gasket sealing.