Electrolytic aluminum liquid features include high temperature, more oxidation inclusions, high hydrogen content, and metal and Na content. Electrolytic Aluminum Liquid Features (1) The temperature……

Electrolytic aluminum liquid pretreatment process includes aluminum alloy melting, temperature control, melt purification, and grain refinement. Electrolytic Aluminum Liquid Pretreatment Process Aluminum Alloy Melting Ingredients……

The internal quality defects of aluminum rods mainly include pores and slag inclusions. Whether it is pores or slag inclusions, they can reduce the tensile……

Molten aluminum casting process is the last process for aluminum alloy. Apart from the aluminum melting and refining process, it is an important step for……

Aluminum alloy grain refiner is mainly used to remove hydrogen and scum in aluminum water and purify aluminum alloy melt at high temperature. Its basic……

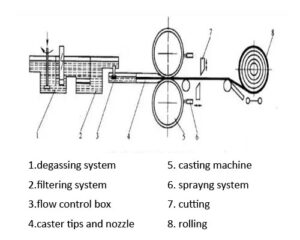

Casting and rolling process of aluminum strip is to use aluminum as the main raw material and melt it with other alloy elements, and then……

Cast rolling zone is the key place of continuous casting rolling process. The length of casting rolling zone not only affects the process parameters, but……

Continuous casting and rolling for aluminum sheet is a process in which liquid aluminum crystallizes in a twin strip caster. In terms of production cost,……

In order to improve the melt quality, it is necessary to understand the purification mechanism of molten metal. The melting degassing process in molten metal……

Aluminium casting refining flux is the most common method to eliminate pinholes in aluminum alloy castings. In order not to cause a lot of splashing……