The metallic element aluminum is the third most plentiful element in the earth’s crust, comprising 8% of the planet’s soil and rocks (oxygen and silicon……

Aluminum products are widely used. To obtain pure aluminum products, aluminum foundry must go through the extraction and refining aluminum process. Known deposits of bauxite……

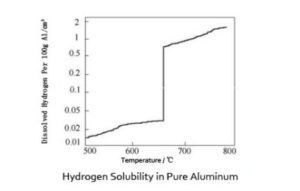

Hydrogen Influence on Aluminum is obvious. Hydrogen is the only gas that is appreciably soluble in aluminum and its alloys. Its solubility varies directly with……

Refractory fiber material refers to the general term for crystalline and amorphous fibrous materials with a refractoriness greater than 1580°C. Therefore, it includes aluminum silicate……

3004 aluminum alloy is used for punching cans, ship decks, food and beverage packaging and other industries. 3004 aluminum alloy punched cans have a high……

With their unique functional characteristics, ceramic filters have become an irreplaceable product in the field of separation and purification. Porous ceramic is a kind of……

It is well known that when melting metals, the molten metals, especially the molten aluminum, usually have solid impurities entrained in suspension, which are harmful……

Iron is the main impurity element in aluminum alloys. In 6063 aluminum rod, the national standard stipulates that it is not more than 0.35. If……

Molten aluminum is extremely reactive, so when it comes in contact with moist air or wet tools, the water decomposes to release hydrogen in the……

Aluminum alloy smelting is one of the most important process links for the production of high-quality casting rods. Flux Refining Process is an important process……