Aluminium Sand Casting is a casting method in which casting sand and core sand are used as molding materials, and liquid metal is filled under……

Permanent mold casting is also called hard mold casting. The casting mold is made of metal materials, such as cast iron, carbon steel or low……

Refractory materials are the basic materials for high-temperature industries. The application fields of refractory products include steel industry, cement industry, non-ferrous metal smelting process and……

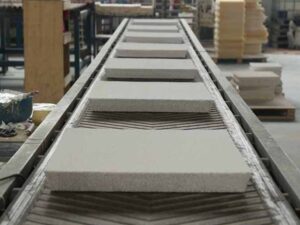

Continuous casting is an advanced casting method. Its principle is to continuously pour molten metal into a special metal mold called a crystallizer. The solidified……

Foundry ceramic filters are made of polyurethane foam plastic and immersed in the ceramic slurry made of ceramic powder, binder, sintering aid, suspending agent, etc.……

The use of aluminum alloy castings is increasing, and the requirements for castings are becoming higher and higher. In addition to ensuring chemical composition, mechanical……

Aluminum alloy smelting and pouring are the main links in molten aluminum casting production. The strict control of the entire process of melting and pouring……

Aluminum is an active metal element, and aluminum easily oxidizes and absorbs the gas in the aluminum casting process. The aluminum oxidation (Al2O3) has a……

On October 11, at the German Aluminum Industry Exhibition 2018. AdTech and Bahrain GMI formally formed an in-depth strategic partnership, they reached strategic cooperation. The……

Aluminum dross recycling has certain economic value. The worldwide aluminium industry produces nearly five million tonnes of furnace waste each year. Known as dross, aluminum……