Recycled aluminum alloy contains more metal and non-metal impurities and must be further refined. Refining methods include filtration, gas refining, flux refining, vacuum refining, and……

In the production of primary aluminum, approximately 273×10^6J of energy is required per ton of aluminum. The energy required to produce alumina accounts for about……

Headbox (front box) installation is important for aluminum liquid level control accuracy, it is one of the key factors affecting the quality of ultra-thin fast……

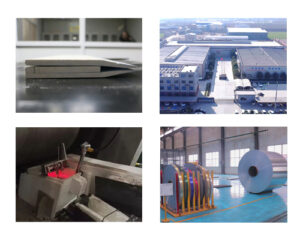

The installation and adjustment of continuous casting tips and nozzles are very important for aluminum sheet casting and rolling process. It is related to the……

During the aluminum alloy smelting process, exhaust gas is the main link that causes environmental pollution. Among the conventional fluxes used in the aluminum smelting……

The molten aluminum feed tip is a key component that directly distributes and transports the molten aluminum to the roll gap during the casting and……

The aluminum caster tip has a great influence on the quality of the cast-rolled strip, especially the uniformity of the velocity distribution and temperature distribution……

The aluminum melt passes through foundries filters, so that the impurity particles in the melt are intercepted by the surface of the filter medium or……

At present, most aluminum foundries use plate filter equipment, which mainly filters through ceramic foam filters. The following issues should be paid attention to when……

The molten aluminum enters the head box from the CFF filter box through the flow trough. There are generally two ways to enter the head……