Fluxes for Aluminum Smelter are indispensable auxiliary materials in the smelting process of secondary aluminum smelting process. In addition to being used as a covering……

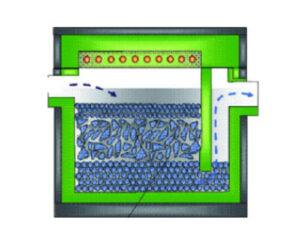

In the aluminum recovery process, CFF aluminum melt filtration is the last purification process close to smelting and casting. Previously, the furnace was refining, lifting,……

Aluminum melt filtration and purification is the use of filtration technology to reduce the impurities and inclusions in the melt before the melt is cast……

For aluminum alloy castings, inclusions and gas are the most important factors that affect their performance and even cause castings to be scrapped. To reduce……

Generally speaking, aluminum purification in furnace includes flux method, gas refining method (active and degradable gas), vacuum purification, and field purification. Among them, flux purification……

CFF filtration efficiency is only related to the thickness of the filter and the speed at which the melt passes through the filter. The greater……

The Aluminum Melt Tubular Filter realizes the dual functions of surface filtration and internal adsorption and trapping of impurities. The basic working principle of the……

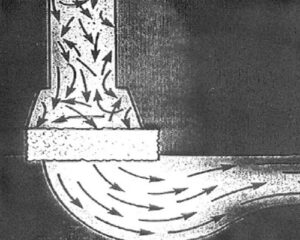

The deep bed filtration device consists of several layers of alumina balls and gravel layers. The particle size selection of the filter material and the……

Both DBF and CFF are based on the same deep filtering technology. Deep Bed Filtration (DBF) and Ceramic Foam Filtration (CFF) technologies are representative of……

Purification of molten aluminum gas purifier refers to the introduction of gas into the aluminum melt or the addition of substances that can produce purified……