It is necessary to combine the use of the correct degassing filter equipment to properly manage the cleanliness of the molten metal. The cleanliness of……

Manufacturing porous alumina ceramic foam filters, using a three-dimensional network structure and organic foam sponge connected to the pores as a carrier, invading it into……

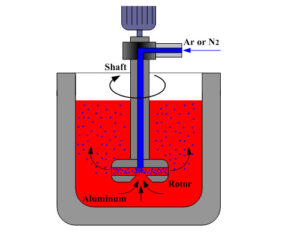

Degassing with fluxing gas can remove the hydrogen and inclusion in molten aluminum. Referring to the fluxing gases, what is contemplated is that a non-reactive……

Flotation slag removal is the use of a certain physicochemical interaction between flux or inert gas and oxides, that is, adsorption and partial dissolution, causing……

Flux slag removal is based on the use of complex compounds formed by impurities and fluxes. Because when the oxides in the aluminum liquid have……

AdTech specially designed Alumina Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. They are manufactured with porosities varying from 10 to……

The metal degassing systems can achieve hydrogen removal and oxidation inclusions removal. The degassing unit has high degassing efficiency, without affecting production. The degassing process……

AdTech ceramic foam filters for molten metal filtration adopt three different specifications of sealing gasket: fiber paper edge; fiber cotton edge, expanded cotton edges. The……

The substantial increase in the ceramic foam filter for molten metal filtration cost of large castings is an important issue that the foundry must consider.……

Alumina Ceramic Foam Filter (CFF) Filtration System for Aluminium Foundry is intended in particular for filtering aluminum alloys and other nonferrous metals and metallurgical applications……