Ceramic foam filter (CFF) is not only good in molten Alu filtration technology, but also easy to use. The initial pressure difference through the melt……

In view of the fact that after the aluminum material is melted, it will continue to oxidize and inhale, causing secondary pollution, so the time……

The purpose of molten Alu purification is to remove the gas (hydrogen) and solid impurities (alumina) in the aluminum liquid. Purification of molten aluminum requires……

Metal when molten in the air will make an oxide skin called slag that floats on top and can be skimmed off. Often, the impurities……

Generally, inclusions, especially non-metallic inclusions, are mixed into the molten aluminum. If such molten metal is rolled after casting or the like and made into……

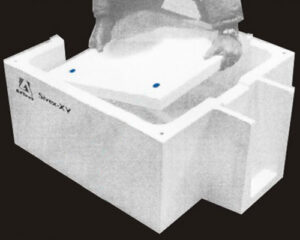

AdTech provides efficient degassing and filtering equipment that includes chambers with respective metal inlets and outlets, and supports in a sequentially spaced relationship. Among them,……

The technical field of degassing and filtering of molten metal relates to the treatment of metals with flux gases and filters. In fact, molten metal,……

It is well known in the field of aluminum casting that various surface defects formed during ingot casting, such as pits, vertical wrinkles, oxide plaques,……

Generally, horizontal continuous casting aluminum alloy rods are manufactured by casting. Specifically, the molten aluminum alloy is cast into an elongated aluminum ingot in the……

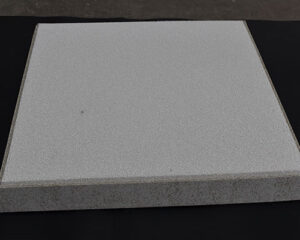

Alumina ceramic foam filter is widely used in the casting molten aluminium filtration, can effectively remove various inclusions of aluminum melt, greatly improve the cleanliness……