Liquid metal filters are located inside the CFF Casthouse between the aluminum melting furnace and the online degassing unit. It is used to remove the inclusions……

By introducing a gaseous chlorinating agent for molten aluminum into the molten aluminum body, sodium is removed from the aluminum. The molten aluminum body contains……

It is known that molten metals such as aluminum include high levels of oxide and/or nitride fragments, which have a negative effect on the solidification……

Aluminum Melt Degassing uses the nitrogen blown into the aluminum alloy melt to be crushed by the rotating silicon nitride rotor, forming a large number……

Aluminum Degassing Unit manufacturer AdTech has long recognized the need for effective nitrogen gas treatment to remove hydrogen and inclusions. Therefore, AdTech online degassing device……

By combining a pair of elongated feed nozzle components with a non-corrosive cushion, a molten metal feed nozzle for a continuous roll casting machine is……

The molten metal enters the gap between a pair of water-cooled continuous caster rolls through a pair of feeding nozzle member funnels. The axes of……

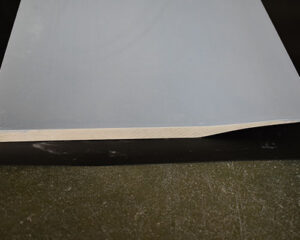

The feeding tip nozzle is by pressing the buffer pad directly into the surface of the outside face of the feed tip nozzle as the……

The casting nozzle gasket is a key component of the aluminum strip continuous casting machine. It directly affects the quality of the strip and the……

Before molten metal is poured into the casting nozzle, it is preferred to heat the nozzle to minimize warpage and to avoid prematurely cooling the……