Degassing of molten aluminum is an essential process in alloy casting. It is done by one of two methods: flux or rotary degassing. The molten……

The ceramic foam filter plate is designed as a disposable item, so it is necessary to provide an effective way to seal the filter plate……

Naturally, there is a great need to improve the filtration and degassing of molten metal to remove or minimize such impurities in the final cast……

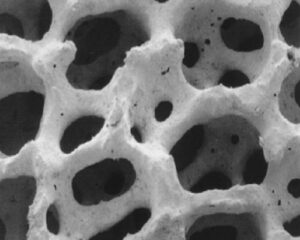

The filtration of molten cast metal has proven to be an effective method to improve overall casting quality. Filtration improves the mechanical and physical properties……

The presence of hydrogen and fine particles in cast products is a serious problem because the final products processed on cast rods (such as continuously……

The impurities in the melt have been identified as the main cause of product failure during production and use. Therefore, melt cleanliness becomes a measure……

The firing of the porous ceramic filter materials is usually carried out at a temperature higher than the temperature at which the glass phase of……

The requirement for the production of aluminum ingots and billets for the preparation of high-quality aluminum products is that molten aluminum is relatively free of……

In fact, molten metal, especially molten aluminum, often contains entrained solids, which are harmful to the final cast metal product. These entrained solids appear as……

As a kind of metal, aluminum has a wide range of applications in aviation, construction, automobile and other industries. With the development of aluminum processing……