As a kind of metal, aluminum has a wide range of applications in aviation, construction, automobile and other industries. With the development of aluminum processing……

The production cost of hot-rolled aluminum billet is high, and the aluminum foil needs to be tempered during the production process, which increases production costs.……

At present, the processes for waste aluminum cans recycling include: manual picking → crushing, shredding → magnetic separation → vibration screening and winnowing → paint……

Molten aluminium is an alloyed aluminum and aluminum alloy high-temperature liquid formed by directly or mixing primary aluminum (aluminum ingot or electrolytic aluminum) with other……

After the die-casting aluminum alloy is melted and refined, the molten aluminum is taken after refining and degassing, the time before and after the refining……

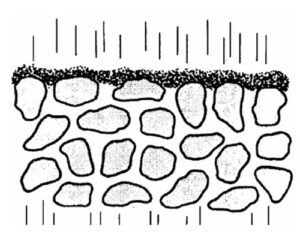

Inclusions and gases in the metal have a significant impact on the strength, fatigue resistance, corrosion resistance, and stress corrosion cracking performance of the material.……

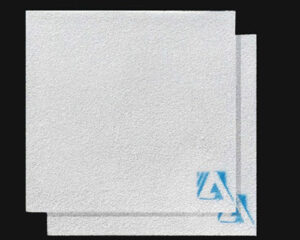

Foam ceramic filtration technology came out in the 1970s and has been rapidly widely used in the United States, Canada, Japan, France, Australia, and Switzerland.……

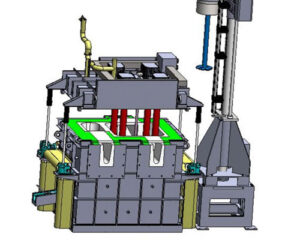

In-furnace purification has its limitations. For high-end aluminum production, online molten aluminum purification technology outside the furnace is required. The cleanliness of the purification process……

Aluminum is one of the most recycled materials on the planet. Today, the global recycling efficiency has reached 76%. The high recovery rates in all……

There are two kinds of Aluminum Casting Degassing: one is chemical degassing, which uses refining flux, the other is degassing by degassing machine. Impurities are……