The impurity elements in 2000 series Al-Cu-Mg and Al-Cu-Mn alloys are mainly Fe, Si, Zn and so on. In Al-Cu-Mg alloys with magnesium content of……

Compared with other purification methods in the purification furnace, the aluminum casting flux refining method and gas refining method have a series of advantages such……

Generally speaking, furnace purification includes flux method, gas refining method (active and degradable gas), vacuum purification, and field purification. Among them, flux purification and gas……

As we all know, aluminum melt purification is generally divided into furnace purification and online purification according to the time sequence of its purification treatment.……

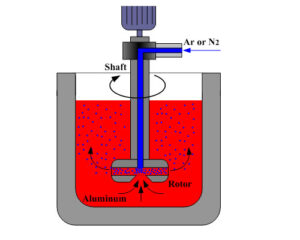

Aluminum alloy liquid degassing of hydrogen can use the adsorption effect of refining agent to achieve the effect of removing oxidized impurities and gas. Inert……

The current general molten aluminum purification method is: after the smelting furnace, connect the degassing box and the filter box through the launder, and then……

By improving the design of online purification equipment, the degree of contamination of the melt after purification is reduced. In addition, through the improvement of……

Because there are many impurities in the aluminum liquid in the electrolytic cell, it must be filtered before casting the aluminum ingot. Common methods include……

Ways to Reduce Casting Losses Control the temperature of liquid aluminum The melting point of aluminum is 660℃. Generally speaking, the casting temperature of primary……

The alloy liquid in the production process of die-casting parts needs to be refined. The adsorption refining method of casting aluminum alloy liquid mainly includes……