The important requirement of the ingot structure is that the inside is composed of fine and uniform spherical casting grains. For different alloy systems, the……

Under stable conditions, when the casting-rolling temperature is constant, the headbox temperature is also constant. Because the melt temperature in the front box is easy……

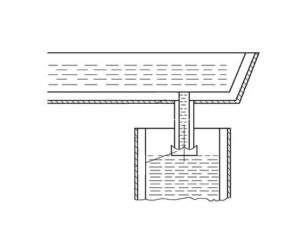

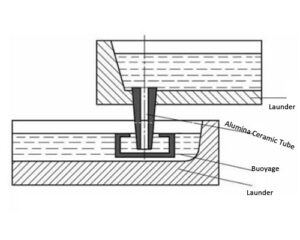

The main function of the casting system in the strip casting and rolling production line is to transport the liquid aluminum from the static furnace……

The main function of the pouring system is to transport the liquid metal from the static furnace to the feed nozzle. During the transportation process,……

Normal casting and rolling shutdowns are prepared shutdowns due to production needs, due to sufficient time and good operating conditions. The shutdown process is as……

Aluminum Casting and Rolling Process Take out the pre-processed mouth fan, gasket, etc. from the holding furnace, check and correct them quickly. Put the nozzle……

The actual size of the ingot does not meet the required size, which is called size inconsistency. The reasons are as follows: Improper flow orifice……

In China, the casting parameters of the casting process are basically in the manual or automatic control system. The foreign countries automatically control the casting……

Equipment inspection before aluminum ingot production Aluminum outlet: mainly check whether there is aluminum slag clogged, if there is, clear it. Outside line rangefinder: Infrared……

Cast non-ferrous metals include aluminum alloys, magnesium alloys, copper alloys, zinc alloys, titanium alloys, and bearing alloys. The equipment for smelting and refining non-ferrous metals……