Degassing process of aluminum in casting is important for high-quality aluminum products. With the increasing demand for high-quality aluminum products, especially in the aerospace industry,……

In aerospace industry, the requirements of casting aluminum alloy castings are very high. Most companies still use inert gas rotary degassing and slag removal operations……

Aluminum purification is an important research and development object of melting and casting production in aluminum enterprises. Rotary nozzle degassing method is widely used, which……

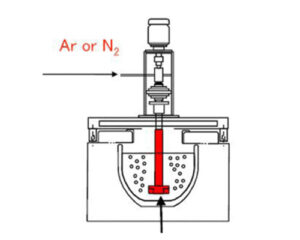

The principle of the floatation method is to pass an inert gas (usually nitrogen, argon or the gas produced by adding salts) into the aluminum……

The purification of aluminum alloy melt is the prerequisite for obtaining high-quality castings. Due to the inhalation and oxidation of raw materials and during the……

With the development of science and technology, automotive, shipbuilding, aviation, aerospace, and other manufacturing industries have increasingly higher quality requirements for aluminum alloy castings. In……

During the casting production, the aluminum alloy melt is solidified in the mold. During the solidification of the aluminum alloy melt, the hydrogen atoms in……

In the modern equipment manufacturing industry, “lightweight” has become the consensus of material selection. Especially in the fields of modern aerospace, transportation, light industry and……

The degassing principle is different for different degassing unit. At present, the two inert gases commonly used in the degassing process are nitrogen and argon.……

As we all know, because aluminum alloy wires have incomparable performance with ordinary steel core aluminum stranded wires, aluminum alloy wires have been widely used……