Due to the high content of non-metallic inclusions, hydrogen, and sodium in the electrolytic aluminum liquid, the direct batching of 8079 aluminum alloy cast-rolled plates……

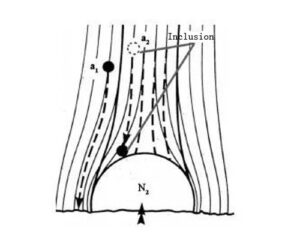

Nitrogen refining generally requires a lower temperature of the molten aluminum, although lowering the temperature reduces the diffusion rate of atomic hydrogen in the molten……

There are many purifying methods for molten aluminum in the furnace, including flux refining, and online degassing and filtration. Practice has proved that nitrogen refining……

It is more important to use suitable aluminum liquid purification methods, so as to eliminate pores and inclusions in aluminum castings. It is necessary to……

Al Alloy Refining Flux is used in a variety of aluminum alloy melts and can be used for pure aluminum smelting, refining and slagging. When……

The internal quality of aluminum ingots refers to both chemical composition and internal organization. Therefore, strictly controlling the impurity of aluminum ingots and preventing the……

The difficulty in the production of aluminum ingots for remelting is ripple control. The continuous casting machine adopts chain transmission, which has poor transmission stability……

Refine Flux contains adsorptive and fusing compounds, which can strongly adsorb and fuse oxides and aluminum slag. These foreign objects are adsorbed on the bubbles……

The aluminium degassing of die-casting aluminum alloy is very important to the mechanical properties of the casting. The hydrogen absorption is the main reason for……

With the continuous expansion of aluminum alloy materials in various fields of the national economy, higher and higher requirements are put forward for the internal……