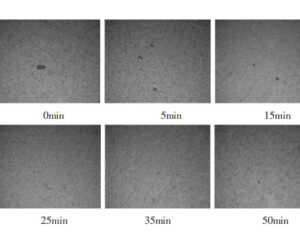

The purification treatment technology of aluminum melt is the first key process that determines the application of aluminum alloy materials. It determines whether aluminum alloy……

Refractory coating is crucial to improving the quality of castings. Compared with sand casting, metal mold casting has better metallurgy properties and casting surface properties,……

For a specific casting, if the mold coating is selected properly, the application operation is stable and controlled. In theory, qualified castings can be obtained.……

How to prepare such a variety of complex raw materials into qualified recycled aluminum ingots is the core issue of recycled aluminum production. The first……

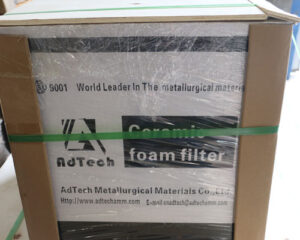

Alu Ceramic Foam Filter combines the pretreatment of scrap aluminum and re-casting, which not only shortens the process flow, but also avoids air pollution to the……

Alu Asian Foundry Filters used in Norway Aluminium has the following main characteristics: high mechanical strength, high temperature resistance, no slag, high temperature impact resistance,……

Ceramic Foam Filter Price from China is not expensive to European aluminum factories, and the quality is stable. China’s Ceramic Foam Filter Factory can provide……

The flux for slag removal in the aluminum alloy melt mainly through three methods of adsorption, dissolution, and compounding. The dissolution is mainly achieved by……

Alkali metals removal is also important in aluminum smelting and casting process. Alkali metals and alkaline earth metals in aluminum melt mainly come from alkali……

With the progress of aluminum alloy processing technology and the development of aluminum alloy flux purification technology, some new characteristics have been presented in the……