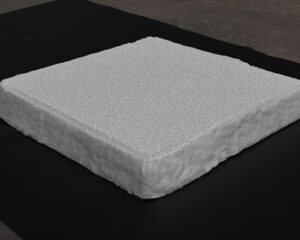

The purification of molten metal plays an important role in improving the mechanical properties of castings. At present, the filtering device used to purify the……

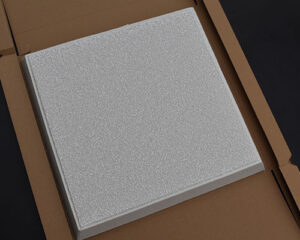

Molten metal usually contains solids, such as metal oxides and other impurities, which may cause the final cast product to have undesirable characteristics. Ceramic foam……

The application is more and more extensive, and the quality requirements for aluminum alloy castings are getting higher and higher. In addition to ensuring chemical……

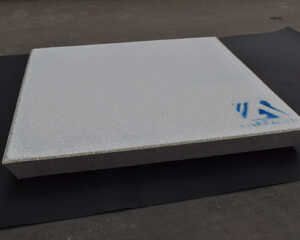

Refractory Ceramic Foam Filters are a key technology in the production of aluminum foil blanks. It is the prerequisite and guarantee for processing high-quality double……

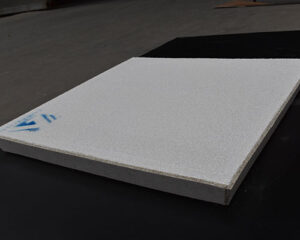

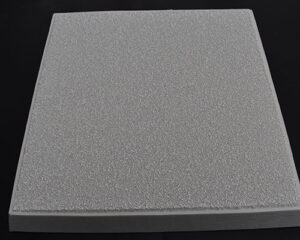

Ceramic foam filter aluminum alloy filtration adopts a three-dimensional network structure and uses organic foam with interconnected pores as a carrier to penetrate the thixotropic……

Molten Aluminum Foam Ceramic Filters is an economical method of removing aluminum inclusions in aluminum melting and casting plants. Due to the different conditions of……

In order to obtain a high-quality product, it is necessary to remove the inclusions. Liquid metal filtration through ceramic media is an effective way to……

In order to manufacture aluminum products with acceptable characteristics, such as beverage cans and aircraft fuselage parts, aluminum must be substantially free of inclusions and……

The ceramic filters for metal casting can effectively remove the large impurities in the molten aluminum and absorb the micron-level fine particles of impurities, thereby……

Alumina ceramic foam filter foundry is mainly used for filtering aluminum and aluminum alloy in cast house. These filters are machined to tight dimensional tolerances,……