The aluminium melting flux should be thoroughly dried beforehand, so as to remove the moisture, which can improve the refining effect and prevent explosion accidents……

Casthouse Flux is mainly a mixture of chloride and fluoride salts and other additives. Generally, the covering flux requires a small surface tension and a……

The main function of aluminum smelter flux is to remove slag and gas, and is widely used in aluminum furnaces and foundries. The slag removal……

Foundries flux is an indispensable auxiliary material in the smelting process of the secondary aluminum salt smelting process. In addition to being used as a……

Powder fluxes can purify the molten mixture of aluminum and silicon before casting. Powder fluxes contain carbonate and fluoride. Castings are made from aluminum-silicon alloys,……

AdTech has developed aluminum granular fluxes. Granular Fluxes have the best impurity removal and purification treatment effect, and show the minimum value in the environmental……

A good aluminum foundry refining agent should have a strong ability to adsorb and dissolve inclusions, a low melting point and good slag-aluminum separation performance,……

The molten aluminum refining fluxes are mainly used for degassing and removing inclusions of metal melt. AdTech refining flux is white powdery fine particles. The……

There are many types of fluxes used for aluminum alloy smelting, which can be divided into two categories: covering agent and refining agent. The molten……

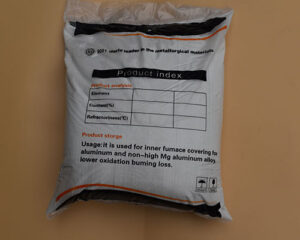

The covering agent can generate a molten layer to protect the metal from oxidation and hydrogen absorption. They gather oxides and non-metallic materials in the……