For the technical transformation project of the 16-ton melting and casting production line of Northwest Aluminum Co., Ltd., our company designed an online degassing unit,……

In the launder system construction, the molten metal flows The cross-section of the launder for casting molten metal is a U-shape that opens and widens……

The launder transfer system is designed to transfer and delivery of molten metal from a melting furnace. It can smoothly transfer the metal up and……

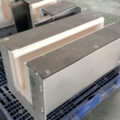

Insulated Launder is placed in the liquid inlet or liquid outlet of the smelting furnace. Insulated Launder is also called Refractory Troughs, Molten Metal Transfer.……

AdTech’s High Aluminum Launder industry has accumulated many years of research and accumulation. Based on the survey results of key enterprises in the industry and……

Ceramic Fiber Launder is mainly used for the distribution of aluminum liquids with high insulation requirements, such as the active flow cell on the casting……

Our refractory technologies may allow producers to avoid the need to “super-heat” the metal in in-line equipment, and most importantly, reduce holding furnace temperatures. AdTech……

In the aluminum processing industry, it needs equipment to re-injected liquid metal from smelting furnaces to holding furnaces. So that the liquid metal can flow……

When the aluminum liquid flows in the refractory trough, the surface aluminum liquid is in contact with air over a large area and is oxidized……

Metal Transfer Runner System is also called Ceramic Launder, Casting Launder. It is a silicic acid fiber product, and mainly suitable for liquid aluminum distribution……