The alumina foam ceramic filter plate is specially developed by AdTech for the purification of molten aluminum. The molten aluminum flows through the tortuous and……

Examples of the ceramic foam filter application effect for molten aluminum Aluminum Profile Production Alcoa’s factory used to use 100% waste to produce 6063 alloy……

In aluminum casting production, the casting rejection rate due to casting defects such as non-metallic inclusions generally reaches 50% 60% of the total number of……

Whether it is flux slag removal or other refining methods, the oxide inclusion particles suspended in the melt cannot be separated clean, especially the suspended……

Alumina has excellent strength and resistance to high-temperature impact and chemical corrosion. Therefore, it is suitable for casting of all aluminum alloys. The alumina ceramic……

With the rapid development of casting industry, the requirements for cleanliness of molten metal and casting performance are higher and higher. In recent years, molten……

Function of Molten Aluminum Ceramic Foam Filter: Removing impurity and slag: purifying molten aluminum alloy and removing hydrogen at the same time; After filtration, the……

High quality foam ceramic filter for molten aluminum plays a very important role in improving casting quality. It can effectively filter liquid and solid non-metallic……

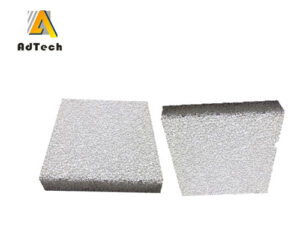

The molten AL ceramic foam filter plate is a new type of filter plate made of industrial sponge as a carrier, filled with heat-resistant ceramics,……

Foam ceramic filter plate is an effective way to remove inclusions in molten aluminum, this filter has been verified by users for a long time……