AdTech provides a refined flux with high purification efficiency for aluminum or aluminum alloy melt and suitable for rotor injection devices. After the refining agent……

In the casting process of aluminum rods, the aluminum liquid in the mixing furnace needs to undergo deoxidation and other processes, usually by adding calcium……

The position of the fixed hole of the launder gate should not be lower than the lower limit of the molten aluminum height of the……

The Refractory Dam is realized by the following technical solutions: including runner baffle, rear guard plate, front guard plate, sealing groove, fixing hole, mounting hole,……

The same level hot top casting system uses a unified flow supply and trough-type distributor to connect multiple hot top molds. Make the metal liquid……

Aluminum alloy melting is the first process of aluminum alloy processing, and it is also a crucial link. The technology of alloying, purifying and refining……

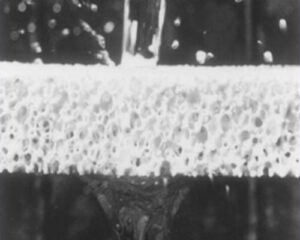

The ceramic foam filter for foundry is installed in the filter box between the furnace and the distributing launder. The filter box is made of……

Inclusions and gases in the metal have a significant impact on the strength, fatigue resistance, corrosion resistance, and stress corrosion cracking performance of the material.……

Foam Ceramic Filter for Aluminum is mainly used for continuous purification of aluminum water, with good deep filtration effect. The use of molten metal filtration……

Refining agents are not unfamiliar in the chemical industry, but there are many varieties of them with or without sodium refining agents, in addition to……