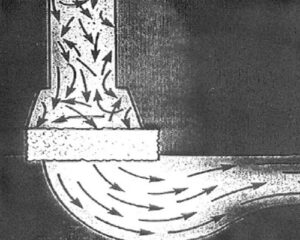

The casting tip is directly connected to the roll gap, filling the aluminum melt between the casting roll gaps steadily and evenly. It not only……

The operation of the alumina ceramic plate refers to the process from the discharge of the static furnace to the casting and rolling of the……

The mouth of the mixing furnace (furnace hole) is equipped with an aluminum liquid flow control device. In order to make the aluminum liquid flow……

The transfer launder is the channel through which molten aluminum flows from the static furnace to the front box. In order to avoid the heat……

The ceramic foam filter is a sheet filter, which is installed online between the metal processing system and the casting equipment. The ceramic foam filter……

The sedimentation operation often takes a long time, and the suspended solid particles in the liquid cannot be completely separated. The filtration is not only……

Filtration is the most effective and reliable means to remove non-metallic inclusions in aluminum melt. In principle, there are cake-like filtration and deep filtration. The……

After the aluminum melt is refined in the smelting furnace, refining in the static furnace and online refining, the gas content has been greatly reduced,……

Foam ceramic is a kind of sponge-like structure and used to filter aluminum melt. The ceramic foam filter is a filtering device that uses ceramic……

Some factories use ceramic filter devices. The outer shell of the ceramic filter devices is welded with steel plates, lined with aluminum silicate fiber, and……