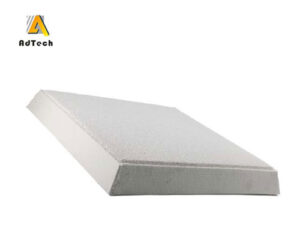

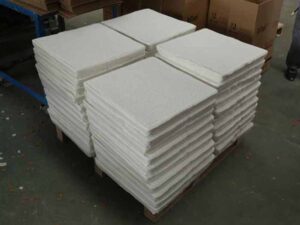

In order to be used for various levels of heat dissipation during casting, ceramic casting filters must be more robust. The best quality materials are……

Degassing in aluminum casting is important because of the uniqueness of hydrogen in molten aluminum is a gas with obvious solubility. When the temperature of……

The complex degassing aluminum casting is a new technology with the electromagnetic pump low-pressure casting technology as the core, aluminum smelting and molding compound purification……

Purification process of liquid aluminum alloy is the main means to improve the comprehensive properties of aluminum alloy. In the purification process, the purification gas……

Furnace refining refers to the refining process. The pretreatment of the aluminum liquid includes furnace refining and online purification. The results show that the temperature……

Liquid Aluminum Purification becomes one important step for casting aluminum alloy. With the development of modern science and technology and the demand of modern industry,……

There are two main causes of aluminum slab slow bending: (1) The dummy bar head of the flat ingot is not placed smoothly, and the……

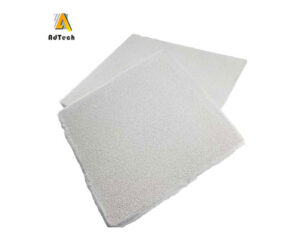

Ceramic Foam Filters for Casting and fluxes are used to remove the inclusions by most aluminum foundries. Liquid aluminum reacts chemically with oxygen, nitrogen, sulfur,……

Ceramic filters are responsible for removing any impurities and providing the filter with long-term durability. The primary requirement of the die-casting industry is to deliver……

“Degassing” generally refers to the removal of gases from the alloy, while “refining” refers to the removal of inclusions in the alloy. The purpose of……