Ceramic disc filter needs to use properly, otherwise, the effect is worse than other filters. The area of metal passing through the filter should be large enough to prevent the casting speed and pouring time affected by the installation of the filter. Therefore, the factors of slag collection, filter and damping should be considered in the process.

The design of the system should ensure that all the aluminum alloy liquid passes through the ceramic disc filter (if part of it fails to pass, the aluminum liquid will be impure, and turbulent flow will be generated, and slag will be formed by entraining air).

The filter area of the ceramic foam filter should be large enough to not affect the flow rate of aluminum alloy liquid (the minimum flow rate should be located at the minimum section of the sprue).

There should be enough space before and after the filter to collect inclusions.

Aluminum alloy liquid should be melted in melting furnace (avoid oxidation and slag removal treatment) and refining slag removal and degassing in holding furnace. Because the filtration capacity of the filter is limited, the aluminum alloy liquid that is too dirty will cause the aluminum alloy liquid filtered last to be dirtier than the aluminum alloy liquid filtered first.

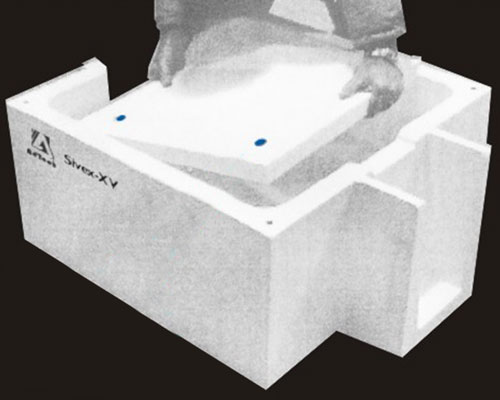

When the ceramic foundry filter is placed horizontally, the best way is for liquid metal to pass through the filter from bottom to top.

Horizontal placement: the use of the Porous Ceramic Filter area is large.

From top to bottom: in the initial stage of filtration, there is a sprinkling phenomenon in the filtered liquid flow; with the filling of the liquid below, the phenomenon disappears.

From bottom to top: after filtration, the liquid flow has no sprinkling phenomenon.

Vertical placement: At the beginning of filtration, the utilization area of the Ceramic Filter for Foundry is small.

There is no shower phenomenon in the filtered liquid flow (there are many small streams in the shower.