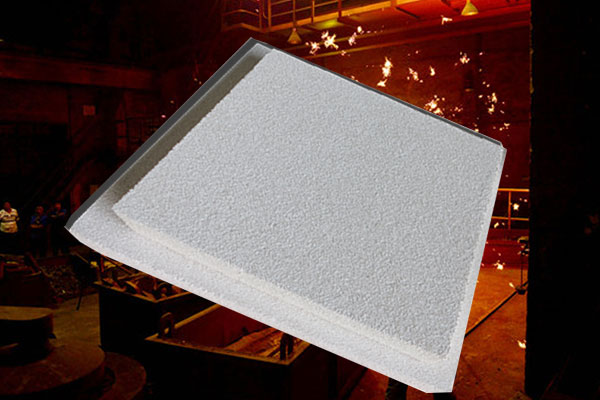

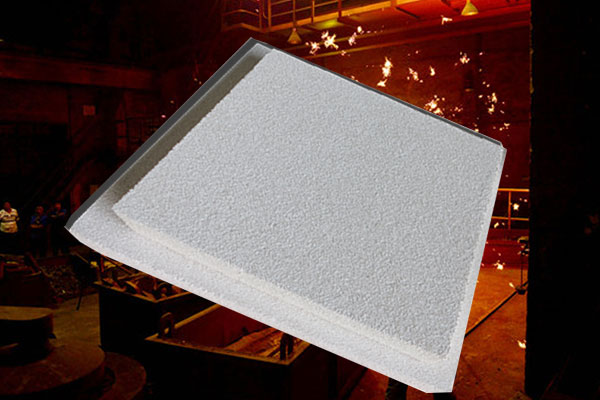

Ceramic Filter Bahrain Aluminum is a kind of representative porous ceramic filter, which has high resistance to molten aluminum attack and is used in filtering molten aluminum.

The most common preparation method for Ceramic Foam Filter For Metal Filtration is the polymeric sponge method which involves the impregnation of polyurethane sponges with slurries containing ceramic particles and appropriate binders followed by pyrolysis and sintering at a special temperature.

Ceramic foam filter has the advantages of high porosity, high mechanical strength, stable chemical performance, strong corrosion resistance, high adsorption rate, good filtering function, and good thermal shock resistance.

Ceramic Filter Bahrain Aluminum is mainly used in the purification process for the production of non-ferrous alloys such as aluminum and aluminum alloys.

The Chairman of the Board of Directors of Bahrain Aluminum BSC (Alba) announced the commissioning of Alba’s waste can lining (SPL) treatment plant, which cost 37.5 million US dollars-the first such waste treatment plant in the region.

The chairman of Alba said that Bahrain and Alba have created many firsts in the region. With the commissioning of the SPL treatment plant, the waste tank lining is transformed into a value-added product to once again set a benchmark for sustainable development. A proper balance has been struck between economic gains and social returns.

“To change the way we do things, we need to challenge the existing reality. Without environmental sustainability, we cannot meet the challenges facing the world today. The SPL processing plant embodies our mission, which is to always make ESG our top priority , And do more for our community. I thank the Supreme Environmental Council, the Ministry of Industry, Commerce and Tourism for continuous guidance and support, our technology providers and all our partners, for turning our vision into reality, “Alba’s CEO said.

The project covers an area of 26,000 square meters and has an annual production capacity of 35,000 tons of SPL. Construction began in December 2019. Alba will be able to convert the processed SPL into valuable products that can be used in other industries, such as cement, thanks to this zero-waste approach.