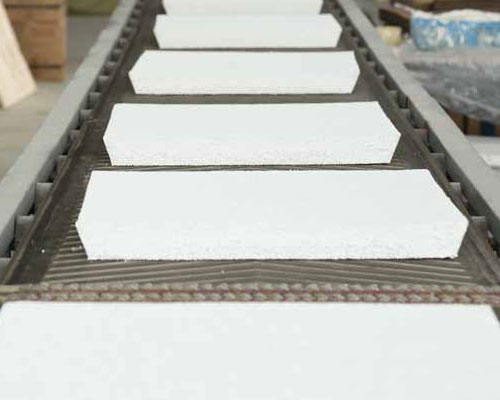

Ceramic filter board can effectively filter non-metallic solid inclusions in aluminum and aluminum alloy melts. It uses foam sponges with a high open cell structure and high purity ceramic materials, produce pores of molded foam filter plates under strict quality control hole ratio. It has sufficient sintering and good bending strength to ensure high efficiency filtration. The company offers different sizes of pores, all of which are available in different sizes.

Ceramic Foam Filter Plates are widely used in the filtration and purification of various aluminum and aluminum alloy melts such as continuous casting, semi-continuous casting, gravity casting, and low-pressure casting. In addition to the general specifications, it can be designed according to customer needs.

Ceramic filter board has a three-dimensional network structure which makes it widely used in the field of melt filtration of aluminum and aluminum alloys.

Although it constantly tries to apply to environmental protection, chemicals, energy, petroleum, bioceramics and catalyst supports, it is limited in many areas due to its low strength, easy slag and low dimensional accuracy. application.

At present, alumina ceramic foam filter manufacturers are still targeting the molten filtration of aluminum and aluminum alloys, and have not yet been able to research related products to replace their applications in the market.

Therefore, with the development of precision in aluminum and aluminum alloy processing industry, alumina foam ceramics will be further developed and applied.

There are various methods of preparing the Ceramic filter board, such as a foaming process, an organic foam impregnation process, a sol-gel process, etc.

Among them, the organic foam impregnation process has the advantages of less equipment, low manufacturing cost and simple process, and is widely used in ceramic foam manufacturers.

The ceramic foam filter is a porous ceramic body with a three-dimensional lattice structure. It is made of a porous polyurethane sponge acting as a skeleton, which is prepared by sizing, drying and baking. The organic precursor of the three-dimensional network structure is removed to form an open porosity. A porous structure of a grid structure having a high specific surface area and a low pressure drop.