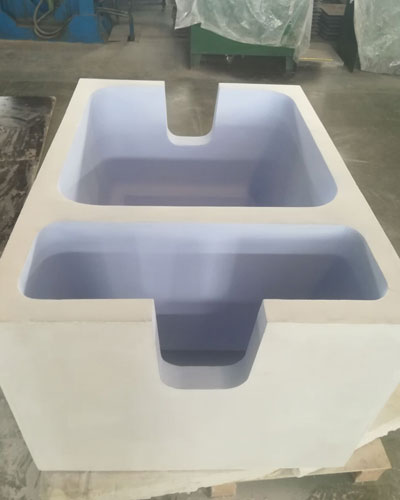

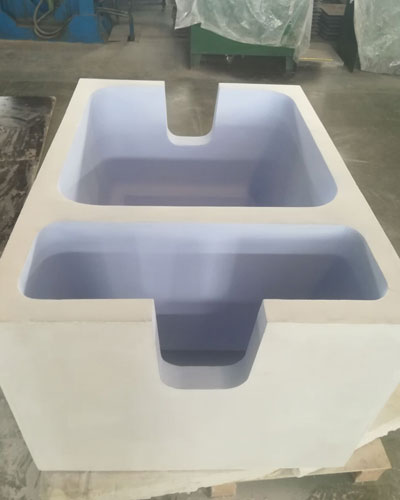

Ceramic filter device currently used in some factories. The outer shell of the filter is welded by steel plates, lined with aluminum silicate fiber felt, and then built with a layer of light refractory bricks, and the inside is brushed with talcum powder. The inner cavity of the filter is divided into two compartments A and B by porous ceramic plates or silicon carbide plates.

The chamber is a filter chamber, the filter tube is assembled on the partition hole, the assembly part is sealed with aluminum silicate fiber felt, and the B chamber is a storage chamber, which collects the filtered metal. There is a heating cover on the upper part of the filter with resistance heating wire inside. The thermocouple measures the temperature continuously, and the electronic potentiometer automatically controls the metal temperature in the filter. There is a discharge eye at the bottom of the filter. The melt enters the filter chamber A connected to it along the launder from the static furnace, then seeps out through the micropores of the filter tube, collects in the storage chamber, and finally enters the crystallizer through the flow plate.

Pay attention to the following issues when designing and using ceramic filter device

According to the requirements of the product, select the filter material with the appropriate pore size. Improperly increasing the filtration accuracy will increase the tendency of the ingot to produce coarse crystals and feather crystals.

From improving the filtering effect and service life of the ceramic filter, the effective filtering area of the filter should be increased as much as possible, that is, the multi-tube filter should be used.

The filter tube should be installed tightly and seamlessly to prevent short circuits.

Before use, the filter should be fully preheated, and the preheating temperature should not be lower than 720℃. In the interval between casting and melting, attention should also be paid to heat preservation to prevent condensation.

In order to meet the requirements of fine filtration and to increase the service life of the filter, it is best to use glass cloth to coarse filter the melt before the ceramic filter.

Reasonably arrange production, and try to avoid obstructing the effective use of filters due to frequent alloy transfers.

When filtering, it is strictly prohibited to sprinkle flux powder in the filter and the launder of the standing furnace.

During the casting process, the static pressure head of the melt should rise steadily to prevent fluctuations in the liquid level and vibration and shock to the mold. Before finishing the casting, the scum on the metal surface of the filter should be removed to avoid clogging of the filter tube.

Prevent secondary pollution of the filtered melt.