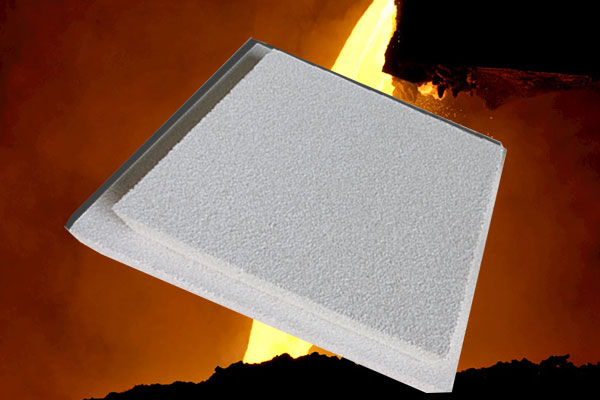

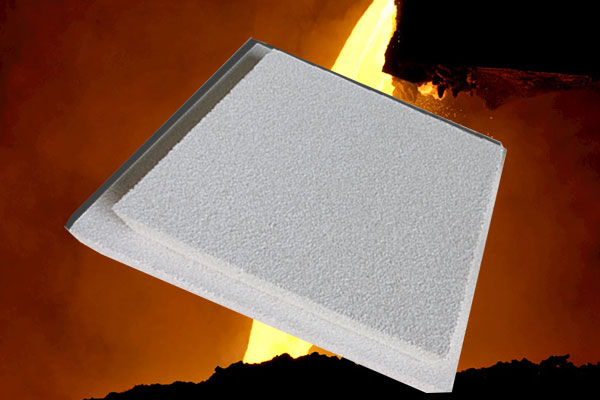

Ceramic Filter India Aluminum can effectively remove the non-metallic solid mixture in the aluminum and aluminum alloy melt, reduce the trapped gas, and provide laminar flow to make the filtered aluminum and aluminum alloy cleaner.

Clean metal can improve the quality of castings, reduce scrap, reduce inclusion defects, improve the quality of aluminum alloy and other non-ferrous alloy castings, and reduce the cost of castings. Its maximum use temperature is 1200°C.

A gasket is installed on the edge of the Ceramic Filter India Aluminum; the gasket ensures the correct and tight position of the filter in the filter box.

There are different types of gaskets, such as ceramic fiber gaskets, and alumina ceramic foam filters without gaskets can also be provided.

These types of ceramic foam filters have been favored by customers from Europe, India, the Middle East and the United States for many years.

India’s leading aluminum producer Bharat Aluminum Co., Ltd. recently won two 2021 CII Energy Conservation (ENCON) awards for the best energy management of its power plants. BALCO’s 1200MW power plant became the national champion-Chattisgarh with a 4.75-star rating, and its 540MW power plant received a 4.25-star large category certificate. Both certificates attest to BALCO’s operational excellence.

Regarding this important achievement, BALCO’s CEO and Director said: “At BALCO, we are committed to maximizing energy savings. Through these efforts, we aim to achieve the greater goal of creating a sustainable future for future generations. Contribute to the rapid development of the country. BALCO has always been an early adopter of smart technology to improve operational efficiency, which further strengthens the energy optimization, safety and productivity that we carefully cultivate throughout the organization. We are committed to promoting environmental and sustainable Develop the social and governance (ESG) dimension to build a greener tomorrow. Therefore, we are actively exploring innovations that help reduce our carbon footprint as early as possible in the creation process.”

Congratulations to BALCO for obtaining this prestigious recognition, the Managing Director of NTPC GE Power Services Limited said: “We are proud to work with BALCO and work together to achieve business goals, while keeping in mind the principles of zero harm, zero harm, waste and zero emissions. We are We will work together to achieve sustainable operations through effective energy management, safety and productivity practices.”

BALCO’s 1200 MW and 540 MW power plants are known for various energy-saving innovations and improvement projects. The factory has ensured 100% utilization of ETP discharge water, and implemented nearly 8,000 quality circles and Kaizen projects. In other energy-saving work, BALCO also reduced the power consumption of its aluminum smelter No. 1 electrolysis cell, becoming the electrolysis cell with the best power consumption in India and the Gulf countries, significantly reducing its carbon footprint.