The China ceramic filter supplier provides the CFF installed on the CFF BOX machine to filter the liquid impurities in the aluminum alloy, which can meet the high value-added, high-tech performance of aviation, transportation and other aluminum alloy precision casting production.

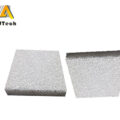

China ceramic filter suppliers use a three-dimensional network structure in which organic foam is connected to pores as a carrier to invade the thixotropic alumina slurry. The slurry was uniformly coated on the foam skeleton of the carrier, and baked and cured at a high temperature of 1180°C.

China Ceramic Filter Product Advantages

1. Adopt the principle of adsorption and filtration to remove large impurities in molten aluminum and effectively adsorb small impurities of small size.

2. No slag, effectively reducing the pollution of molten aluminum.

4. Good thermal shock resistance and corrosion resistance of molten metal.

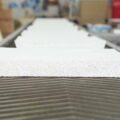

5. Automatic assembly line production, three calibration procedures, accurate size, more in line with the filter box.

6. Improve surface quality, improve product performance, and improve the role of microstructure.

The ceramic filter for casting is composed of open micropores with uniform pore size distribution and interconnected. When the fluid passes through these micropores, the suspended matter in the fluid, colloidal particles, polymer organic matter, etc. are captured or absorbed in the micropores inside the road, so as to achieve the effect of purification and uniform filtration.

The ceramic filter for foundry has high strength, wear resistance, high temperature resistance, corrosion resistance, no pollution, uniform pore size distribution, long service life, simple regeneration, and is used for aluminum liquid filtration and solid-liquid separation.

During transportation and use of the filter plate, the filter plate must be able to withstand a certain external pressure. Therefore, this standard also introduces the compressive strength index as one of the basis for measuring the quality of the filter plate. The higher the compressive strength, the more durable the product and the better the quality, and vice versa. This standard specifies that the compressive strength index should be greater than 0.5MPa.

Storing ceramic foam filter plates in aluminum plants: They should be stored in a ventilated and dry environment to prevent moisture, and no objects should be placed on them.

Ceramic Filter Supplier AdTech offers Filter Pore Size(PPI):10/20/30/40/50/60. 30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry. Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates. Aviation and high-quality aluminum materials usually use the 30-60ppi ceramic filter.