The ceramic foam filters have the advantages of good chemical stability, high specific strength, high-temperature resistance, thermal shock resistance, large specific surface area, good slag removal effect, simple operation, easy matching with other parts, and low cost. Therefore, ceramic foam filters molten metal filtration have become a conventional purification method in aluminum foundry.

Ceramic foam filter molten metal filtration technology came out in the 1970s and has been widely used in the United States, Canada, Japan, France, Australia and Switzerland.

In recent years, some new technologies for the purification of molten aluminum have been studied, such as vacuum dynamic processing, ultrasonic continuous degassing purification, corundum ceramic filters, etc., and they have received good results. However, these technical methods are relatively complex and costly, and it is difficult to mass promote them in production.

As for the metal filter and fiber cloth filtration, only large inclusions in the aluminum alloy melt can be removed, but the inclusions below micrometers cannot be removed. The metal filter will also pollute the aluminum alloy. The use of ceramic foam filters for aluminum foundry can filter out fine inclusions and significantly improve the mechanical properties and appearance quality of the castings.

Using the right High-Temperature Materials will affect your productivity in a positive way! AdTech offers alumina ceramic foam filters for aluminum foundry.

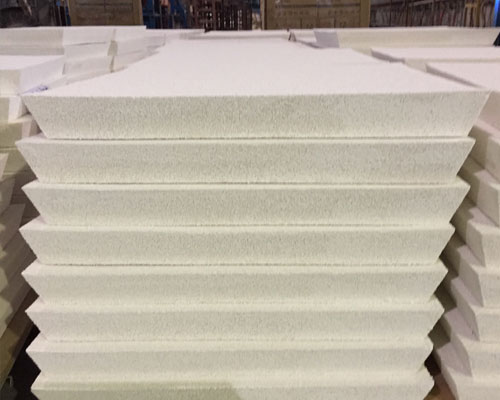

AdTech specially designed Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications.

The alumina ceramic foam filter has a multilayer network and multi-dimensional through holes, and these holes communicate with each other. During filtration, molten aluminum carries inclusions along the tortuous channels and pores. When molten aluminum contacts the foam skeleton of the filter plate, molten aluminum will be directly intercepted, adsorbed, and deposited. When the melt flows in the hole, the filter plate channel is bent, and the melt flowing through the channel changes the flow direction, and the inclusions collide with the hole wall anvil and firmly adhere to the hole wall.