Ceramic Foam Filter

Ceramic foam filter (AL2O3 for aluminum) is a kind of high-adsorption ceramic filter plate. CFF foundry Filter adopts a three-dimensional network structure. It uses an organic foam as a carrier.

Ceramic foam filter adopts four correction center distances and an automatic extrusion process. So the slurry is evenly applied to the foam frame of the carrier. After curing and drying, the foam filter was successfully fired at a high temperature of 1680 degrees. It is in the filtering box for filtering impurities in molten aluminum alloy. AdTech foam ceramic filter can meet the requirement of production in high-tech performance aluminum alloy.

Technical Parameter

| Item | Density(g/cm³) | Rupture Modulus(816℃ /Mpa) | Comprehensive Strength(Mpa) | Operating Temperature(℃) | Sealing gasket expanding temperature (℃) |

|---|---|---|---|---|---|

| Index | 0.45 | 5. 5 | 0. 8-1.0 | 1550 | 450-550 |

Pore size

| Mesh Number(PPI) | 10 | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|---|

| Pore Density(PCS) | 8-12 | 18-22 | 28-32 | 38-42 | 48-52 | 58-62 |

Filter Precision

| Pore Size(PPI) | 20 | 30 | 40 | 50 | 60 |

| Inclusions Diameter(um) | 80 | 40 | 20 | 10 | 5 |

| Filtration Rate(%) | 78 | 85 | 88 | 92 | 95 |

Application of Ceramic Foam Filter

Ceramic foam filters effectively remove and absorb large or small impurities in molten aluminum, improving surface quality, product performance, and microstructure effectiveness. The casting filter is mainly used in aviation, transportation, computer hard drives, PS baseboards for printing, canning materials, fan blades for turbojet engines, and other aluminum alloy precision casting.

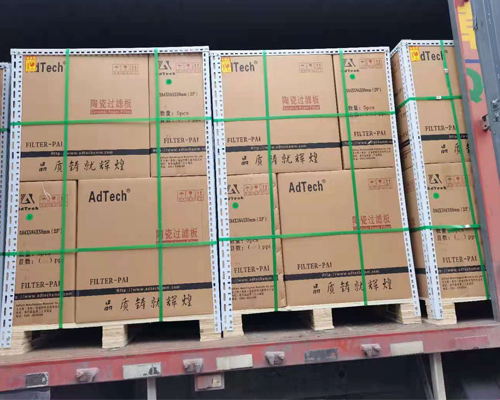

AdTech alumina foam ceramic filters are available in all common sizes: 7″, 9″, 12″, 15″, 17″, 20″, and 23″. AdTech offers a range of porosities from PPI 20 to PPI 60. It can also be customized according to customer needs. Foam ceramic filters are equipped with a gasket on the edges. The gasket ensures the proper and tight position of the filter within the filter box. AdTech ceramic filter adopts sealing gasket in 3 different types, fiber paper material, fiber cotton material, and expanding cotton material.

Foam Ceramic Filter

The basic material of the foam ceramic filter is Al2O3. The heat resistance temperature of the filter is higher than 1180 ° C, and it has very high strength and excellent high-temperature impact.

Among various types of metal oxide ceramics, alumina has better high-temperature stability. Suitable for ceramic coatings and high-temperature refractory products. The thermal conductivity of alumina is the lowest among common ceramic materials, and the thermal expansion coefficient is also close to that of metal materials. The special crystal structure makes it an important electronic material. Good mechanical and thermophysical properties make it an excellent reinforcing phase in metal matrix composites. Among various metal oxide ceramics, alumina ceramics are far ahead in usage. Alumina ceramics can achieve high strength and toughness through phase transformation toughening. It has strong bending strength and strong fracture toughness KIC. Alumina ceramics have strong strength and toughness.

Ceramic Foam Filter Manufacturer

The foam ceramic filter can make the molten metal fill the cavity more evenly. The molten metal has a higher tendency to turbulence during pouring. The liquid aluminum is through the three-dimensional pore structure of the foam ceramic filter and finally converted into a very stable layer flow. Laminar flow has a better filling of the cavity, which reduces the impact of corrosion of the molten metal on the casting cavity. If you are interested in our products, please contact us.