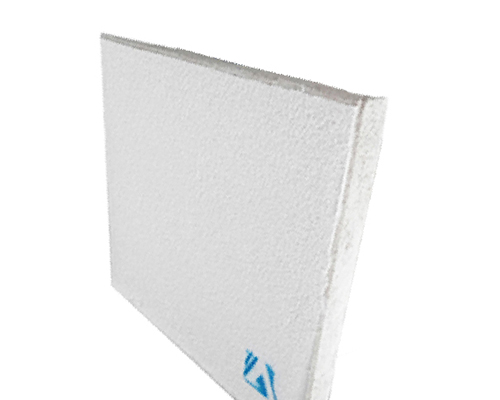

Ceramic foam filter (CFF) is currently the most widely used filter for aluminum melt filtration in Aldel Aluminum Plant. The advantages are high porosity, high filtration efficiency, convenient replacement, low cost, and strong adaptability, and can filter solid inclusions and separate some liquid inclusions.

The ceramic foam filter CFF has excellent corrosion resistance and molten aluminum corrosiveness, effectively removing large impurities in molten aluminum and adsorbing small impurity particles, reducing residual gas and providing laminar flow, thereby making the filtered metal much more transparent.

Advantages of Ceramic Foam Filter Aldel Aluminum

1. Three-dimensional connected network structure, high porosity

2. Large surface area for slag collection and large surface area for filtration.

3. Excellent resistance to thermal shock.

4. Particles larger than the pore size are captured by the upper part of the ceramic foam filter.

5. Smaller particles are captured by larger particles on the filter cake.

6. Small particles are retained in the pores of the filter.

ALDEL is an important supplier to the European aluminum industry and is the only remaining aluminum smelter in the Netherlands with a total production capacity of 150,000 tons. The aluminum smelter plays an important role in helping to balance the Dutch energy grid. As the renewable energy mix increases, the Dutch energy grid becomes more and more important.

Recently, the company has reached an agreement with the operator of a local solar power plant, which will enhance the Aldel aluminum plant’s ability to obtain energy entirely from renewable energy.

Ecorus developed a solar farm on an industrial site in Farmsum owned by the local construction company Gebroeders Borg. The agreement with the Aldel Aluminum Plant will allow the company to obtain the full 4.5 MW of peak power from the solar farm to implement its 10-year plan for complete conversion to renewable energy.