Ceramic Foam Filter Aluminerie Alouette is very important to the quality of aluminum melt, which greatly affects the subsequent processing performance and the quality of the final product.

Fountries all over the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution. On the one hand, during the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state. Easy to oxidize, react with water vapor to absorb hydrogen, and easily form various forms of non-metallic slag. (Such as lining fragments, chlorides, carbides in flux, etc.) and coarse intermetallic particles.

On the other hand, part of the leftover material that constitutes the charge brings some non-aluminum impurities during the circulation process. Because the waste comes from process waste from various processes in the factory and off-site waste, the route is different, the composition is complex, and the quality is poor.

The above-mentioned impurities tend to produce bubbles and inclusions in the cast slab, which seriously affects the purity of the molten metal, and further affects the processing performance, mechanical properties, corrosion resistance and appearance quality of the product.

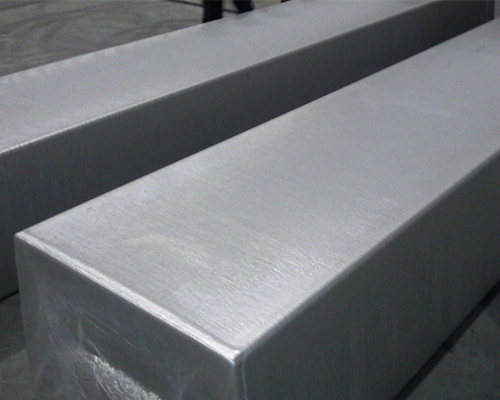

Effect of Ceramic Foam Filter Aluminerie Alouette

The use of alumina filters to purify liquid aluminum brings great benefits to strip foils and their products (such as can blanks, automotive facing materials, PS printing plates, etc.). For manufacturers, there are several obvious advantages:

1. Improve extrusion productivity

2. Extend the life of the mold and reduce the number of mold repairs.

3. Reduce squeezing force

4. Significantly improve the surface quality of aluminum profiles.

With more than 1,000 employees and an annual production capacity of more than 600,000 tons, Aluminerie Alouette is the largest employer of Sept-Îles. It is one of the leading aluminum smelters in the Americas. Since opening in 1992, this cutting-edge company has been at the forefront of environmental requirements.

Aluminerie Alouette broke the historical record in 2020 with an annual output of 620,706 tons of aluminum. In many ways, this is a special year for the largest aluminum smelter in the Americas.

Aluminerie Alouette is the largest aluminum smelter on the African continent, with a nameplate capacity of 550,000 tons per year. The company is jointly owned by Austrian Metals AG (AMAG), Kobe Aluminum and Marubeni of Japan, Koninklijke Hoogovens of the Netherlands, Societe Generale (SGF) and VAW of Germany.