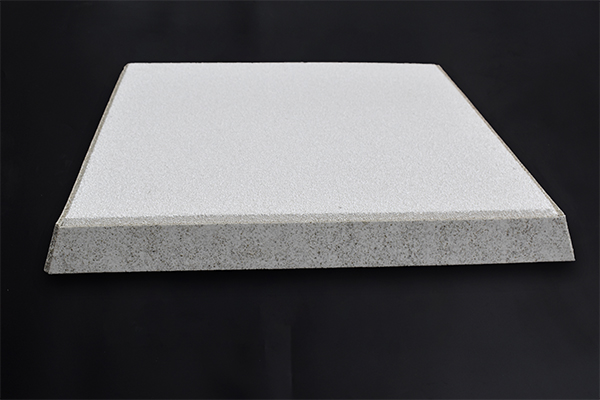

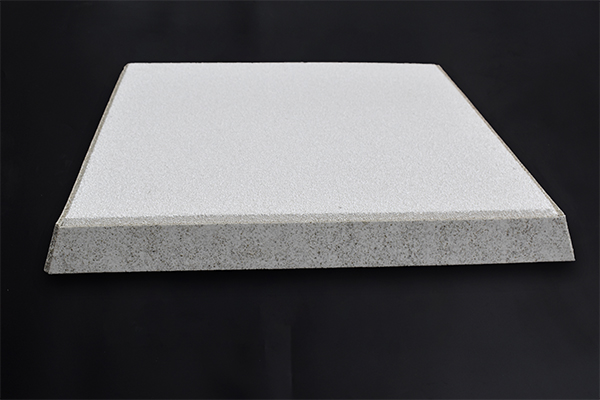

Ceramic foam filter Argentina Aluminum uses good portiforium foam and high purity ceramic as raw material, can remove the non-metal solid mixture from molten aluminum and aluminum alloy casting industry.

Ceramic foam filter has the advantages of even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Ceramic foam filter Argentina Aluminum is widely applied to the aluminum liquid filter equipment of continuous casting, half-continuous casting, gravity casting, and low-pressure casting.

Alumina ceramic foam filters are different from aperture specifications from 20 to 60ppi, with different sizes and shapes.

In 2020, the capacity utilization rate of Argentine aluminum producer Aluar is 70%. At the beginning of 2020, Aluar suspended production due to the spread of the epidemic and the weather.

Aluar said that the company will continue to seek production plans to restart the remaining part of the production capacity.

In March 2020, Aluar announced a reduction in production in response to the Latin American epidemic. Its PuertoMadryn primary aluminum plant in the southern city of Argentina reduced production by 25%.

It is understood that Aluar’s aluminum smelter in Patagonia, southern Argentina, has an annual production capacity of 460,000 tons/year.

Aluar is the only primary aluminum producer in Argentina. It has two aluminum semi-finished products processing plants in Puerto Madryn and a rolling/extrusion plant in Abasto.

Ceramic Foam Filter Argentina Aluminum is suitable for the aluminum and aluminum alloy purification process through physical adsorption and chemical action, which can effectively remove various oxidation inclusions generated during the aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high-quality materials for further deep processing.

Aluminum casting filter also can make aluminum liquid more evenly filled with the cavity, the molten metal has a higher turbulence tendency during casting, and is finally converted into a very stable laminar flow through the turbulent flow of the three-dimensional pore structure, and the laminar flow has better filling of the cavity, thereby reducing the metal solution pair. Impact corrosion of the casting cavity, and significantly reduce the scrap rate, reduce production costs, and increase labor productivity.