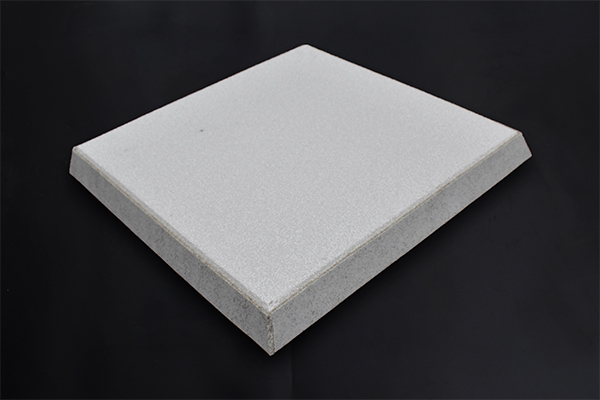

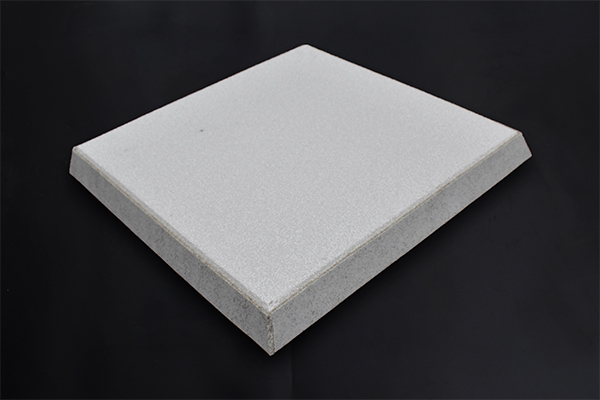

Ceramic Foam Filter Australian Aluminum offers the best way to eliminate non-metallic inclusions. Foreign materials are a major source of quality problems in aluminum casting process. Ceramic Foam Filter helps you increase the aluminum castings quality.

The ceramic foam filter can effectively remove various impurities in the aluminum production line, it also can eliminate turbulence in the metal stream, smooth out metal flow.

The sealing ceramic fiber gasket is attached around the CFF filter plate to help seal the filter plate in the filter box. Put the ceramic foam filter plate into the filter box gently, and press the gasket around the filter plate to prevent the aluminum liquid from floating.

Alcoa will restart the Australian aluminum production line that has been discontinued since 2009. Recently, the company’s stock price has soared due to increased demand for materials.

Alcoa said it plans to restart production of 35,000 tons/year and increase the factory’s production capacity to 95%, with a total production capacity of 358,000 tons/year. The production line is expected to be put into operation for the first time in the third quarter of next year.

Earlier, Alcoa and South32 Ltd. announced plans to restart the idle Alumar factory in Brazil in September.

Aluminium Australia holds a 55% stake in Portland Aluminium, and CITIC Resources and Marubeni (MARUY.US) each hold a 22.5% stake. Alcoa and Alumina Co., Ltd. (AWCMY.US) hold 60% and 40% of Australian Aluminum.

Due to strong global demand, aluminum prices hit a 13-year high in October, and prices have recently fallen.

Ceramic Foam Filter is a kind of effective molten metal filter, it helps Australian Aluminum improve surface quality, improve product performance, and improve microstructure.

Ceramic Foam Filter Australian Aluminum is three dimensional connected mesh structure and high porosity has many advantages, large surface area of slags collection, the large inner surface area of filtering, small flow resistance, good filtering effect, etc.